You should pay attention to this

This section helps to recognize risks and avoid dangers to people and objects.

The devices are intended for industrial applications.

Machine builders must employ qualified personnel. Qualified personnel are people who have been trained to transport, install, commission, and operate electrical drives.

- Transport, storage, unpacking: Only by personnel with knowledge of handling electrostatically sensitive components.

- Mechanical installation: Only by personnel with mechanical expertise.

- Electrical installation: Only by personnel with expertise in electrical engineering.

- Basic tests / setup: Only by personnel with expertise in electrical engineering and drive technology.

The qualified personnel must know and observe ISO 12100 / IEC 60364 / IEC 60664 and national accident prevention regulations.

Read the documentation!

Read the available documentation before installation and commissioning. Improper handling of the devices can cause harm to people or damage to property. The operator of systems using the drive system must ensure that all personnel who work with the drive read and understand the manual before using the drive.

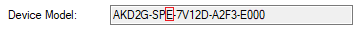

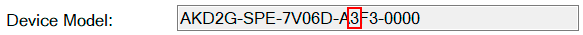

Check Hardware Revision!

Check the Hardware Revision Number of the product (see product label). This number is the link between your product and the manual. The product Hardware Revision Number must match the Hardware Revision Number on the cover page of the manual.

Pay attention to the technical data!

Adhere to the technical data and the specifications on connection conditions. If permissible voltage values or current values are exceeded, the devices can be damaged. Unsuitable motor or wrong wiring will damage the system components. Check the combination of drive and motor. Compare the rated voltage and current of the units.

Perform a risk assessment!

The manufacturer of the machine must generate a risk assessment for the machine, and take appropriate measures to ensure that unforeseen movements cannot cause injury or damage to any person or property. Additional requirements on specialist staff may also result from the risk assessment.

Automatic restart!

|

Risk of death or serious injury for humans working in the machine. The drive might restart automatically after power on, voltage dip or interruption of the supply voltage, depending on the parameter setting. If the parameter AXIS#.ENDEFAULT is set to 1, then place a warning sign on the machine (Warning: Automatic Restart at Power On) and ensure, that power on is disabled, while humans are in a dangerous zone of the machine. In case of using an undervoltage protection device, you must observe EN 60204-1:2006 chapter 7.5 . |

ATTENTION: The drive is ready to operate with pre-configured STO function.

Observe electrostatically sensitive components!

The devices contain electrostatically sensitive components which may be damaged by incorrect handling. Electrostatically discharge your body before touching the device. Avoid contact with highly insulating materials (artificial fabrics, plastic film etc.). Place the device on a conductive surface.

Hot surface!

|

Risk of minor burns! Drives may have hot surfaces during operation. The housing can reach temperatures above 80 °C. Measure the temperature and wait until the housing has cooled down below 40 °C before touching it. |

Earthing!

|

Risk of electric shock! Ensure that the drive is safely earthed to the PE (protective earth) busbar in the switch cabinet. Without low-resistance earthing no personal protection can be guaranteed. |

Leakage Current!

Since the leakage current to PE is more than 3.5 mA, double the PE connection or use a connecting cable with a cross-section >10 mm² to be compliant with IEC61800-5-1.

Deviating measures according to regional standards might be possible.

High voltages!

|

The equipment produces high electric voltages up to 900 V. Lethal danger exists at live parts of the device. Do not open or touch the equipment during operation. Keep all covers and cabinet doors closed. Built-in protection measures such as insulation or shielding may not be removed. Work on the electrical installation may only be performed by trained and qualified personnel, in compliance with the regulations for safety at work, and only with switched off mains supply, and secured against restart. Never undo any electrical connections to the drive while it is live. There is a danger of electrical arcing with damage to contacts and personal injury. Wait at least 5 minutes after disconnecting the drive from the main supply power before touching potentially live sections of the equipment (such as contacts) or removing any connections. Always measure the voltage in the DC bus link and wait until the voltage is below 50 V before handling components. |

Projection of molten particles!

|

If particles fall into the drive or the drive has been damaged, molten drive component particles may be ejected causing injuries. Shut down the drive and wear appropriate protective gear during maintenance work, troubleshooting and fault rectification. System Repair |

Functional Safety!

The assessment of the safety functions according to EN13849 or EN 62061 must finally be done by the user.

Reinforced Insulation

Thermal sensors, motor holding brakes and feedback systems built into the connected motor must have reinforced insulation (according to IEC61800-5-1) against system components with power voltage, according to the required application test voltage. All Kollmorgen components meet these requirements.

Never modify the drive!

Never modify the drive hardware without permission of the manufacturer. Opening the housing causes loss of warranty.

High noise pollution!

|

Fans generate noise of up to |